London-based Solena Materials has secured $6.7M in seed funding for its microbial protein fibres, which are created using AI and provide a plastic-free alternative for the fashion industry.

Making fibres from microbial proteins, Solena Materials has bagged $6.7M in a seed funding round led by Sir David Harding, SynBioVen and Insempra.

It takes the UK startup’s total funding to $10.8M – following a $4.1M pre-seed round three years ago – and will enable it to begin producing its novel protein fibres at scale.

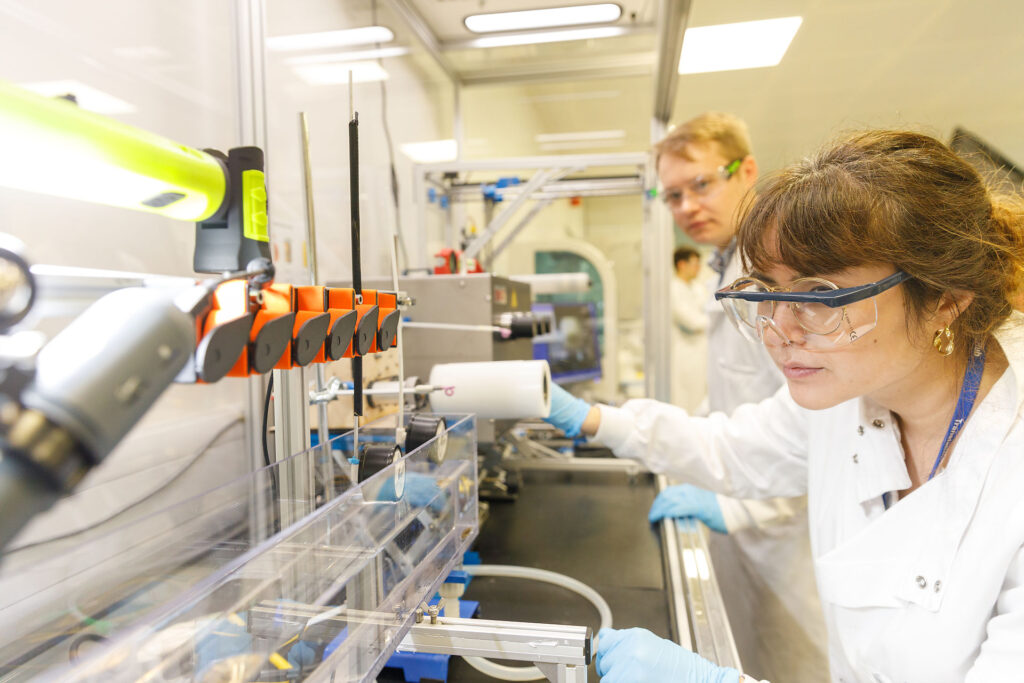

Solena uses artificial intelligence (AI) techniques to design bespoke protein fibres, which are then produced by engineered microbes, offering a plastic-free, biodegradable alternative to conventional clothing fibres.

“We’re creating protein sequences that don’t exist in nature to have the performance specifications we need while also being highly manufacturable,” said Solena co-founder and CEO James MacDonald.

The startup is aiming to launch its debut product with a partner brand in the next three years. Textile and fashion companies would be wise to keep an eye, given that their industry is responsible for 10% of global emissions, and these will surge by more than 50% by 2030 if current consumption rates continue.

Combining AI with biomanufacturing

Solena was spun out of Imperial College London in 2022 by MacDonald, Paul Freemont, and Milo Shaffe, and combines AI with biomanufacturing.

MacDonald developed the technique as a researcher at Imperial, designing protein fibres using proprietary deep neural networks and software tools. The molecular-level design enables the precise tuning of fibre properties, from tensile strength and elasticity to biodegradability and functional performance. This allows them to produce better-performing fashion, sports apparel, and technical textiles.

“The combination of computational design with rapid evaluation in fibre form, directly feeds to scaled-up production and implementation, exploiting established textile technology,” said Shaffer.

“James has created new protein molecules that can form fibres that currently don’t exist. That’s really exciting because no one has been able to do that before – we’ve always had to rely on what nature gave us,” added Fremont. “Now we’re building our own protein fibres from first principles. This will be a paradigm shift.”

Since Solena uses renewable feedstocks for its microbes, it allows the fibres to potentially be produced in a more climate-friendly manner than petroleum-based synthetic textiles or resource-intensive natural fibres. And unlike plastic derivatives, which take anywhere between 20 and 50 years to break down, the company says the novel protein fibres are more immediately biodegradable.

“Investing in Solena Materials aligns perfectly with Insempra’s mission to drive a regenerative revolution by developing sustainable, high-performance ingredients with nature,” said Insempra CEO Jens Klein.

Solena looks to scale up and reduce costs

Harding, one of the investors in this latest round, called Solena’s technology an answer to fashion’s sustainability issues. “Manufacturing wearable materials biologically could be the next revolution in clothing,” he said. “Most clothing today is made of materials derived from fossil fuel feedstock. Hopefully, the materials of the future will be grown in vats.”

About 60% of all clothing comes from plastic, and only a tiny fraction of this is made from recycled plastic. Derived from fossil fuels, plastic production emits more greenhouse gases than the aviation sector, and a third of all plastic waste ends up in soil or freshwater, disintegrating into microplastics that enter the food chain. These tiny particles have already been discovered in the human body.

Meanwhile, every second, the equivalent of one dumper truck of textiles is either landfilled or incinerated around the world. To make matters worse, textile waste has been estimated to increase by about 60% between 2015 and 2030. Plus, there’s the thorny issue of waste colonialism, whereby wealthier nations ship their fashion and clothing waste to developing countries, where they create toxic mounds of garbage.

Solena is among a wave of biomaterial startups looking to fix this mess. Two noteworthy firms also using microbes are Newlight Technologies (US) and Alt Tex (Canadian). The former makes its AirCarbon bioplastic, which can melt the same way as plastic, by feeding marine microorganisms carbon dioxide and methane from dairy farms, while the latter uses microbial fermentation to turn food waste, into biodegradable polymers, which are mixed with additives to create fibres to sell to fashion brands.

Armed with the new funding, Solena is now accelerating its path to market. “This funding will help us expand production capacity, reduce costs, and begin collaborating with partners to launch products made with Solena fibres,” said MacDonald. “It marks an exciting step towards a future where sustainability and performance go hand in hand.”

The post UK Startup Raises $6.7M to Scale AI-Designed Microbial Protein Fibres for Next-Gen Textiles appeared first on Green Queen.

This post was originally published on Green Queen.