In Germany, a quarter of consumers are open to trying cultivated meat made from a 3D printer, a much greater share than in 2019.

As Europe’s leading plant-based market, Germany has always shown openness to food tech innovation, especially its youth.

Last year, one survey found that young Germans trust food produced via new technologies and are willing to buy it three times more than older respondents, who worry about potential health risks.

Now, another poll shows similar results, with 24% of Germans open to trying cultivated meat produced in bioreactors and formed with a 3D printer, much higher than the 13% who said the same six years ago – but older generations seem the least likely to want to give such products a go.

Conducted by Bitkom Research, the survey covered 1,004 Germans aged 16 and over between March and April this year, who were asked if they could imagine eating 3D-printed cultivated meat, and what drove or kept them from doing so.

Cost remains a big concern for 3D-printed cultivated meat

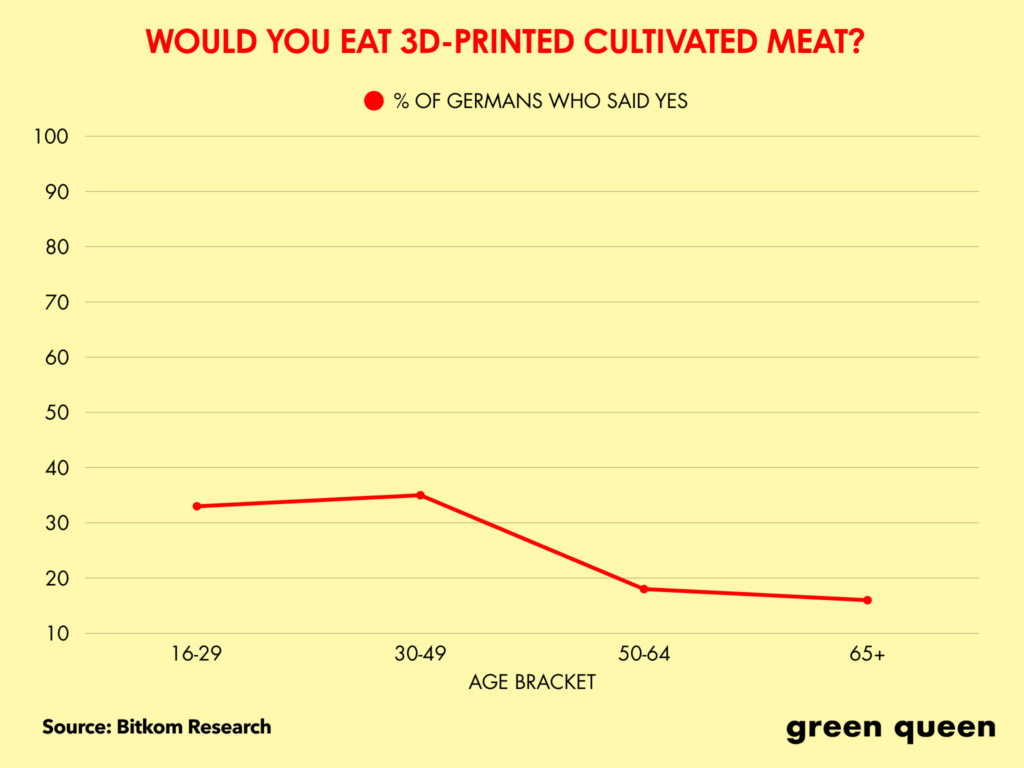

Openness to novel food was greatest among 30- to 49-year-olds, 35% of whom expressed interest in trying 3D-printed meat. This was followed by the 16-29 age group (33%).

However, only 18% of 50- to 64-year-olds say they’d eat cultivated meat made this way, a number that falls to 16% among those aged 65 and over.

That said, about a third (31%) of consumers are convinced that cultivated meat from a 3D printer can contribute to a more sustainable food system. While that’s proof that Germans are aware of the climate benefits of these proteins, it highlights the need for further education.

Perhaps more crucial to consumers is the cost to their wallet, with only 7% willing to pay more for these foods. In fact, a sixth of them viewed 3D-printed food as purely a luxury product.

It’s reflective of a key bottleneck for the cultivated meat industry. Since it’s a new technology currently being produced on a small scale, these proteins are expensive. A lot of work has been done over the last decade to bring prices down – and dramatically so, in some cases. According to McKinsey, it will take until at least 2030 for cultivated meat to be cost-competitive with its conventional counterparts.

And in line with some expectations from the survey, some cultured meat startups have focused on high-value species and positioned them as premium products for the cost economics to make more sense. For example, BlueNalu is working on bluefin tuna toro, Forsea Foods on Japanese eel, and Vow on quail and foie gras.

Germans are also most likely to be introduced to these proteins through a foie gras product, with Parisian startup Gourmey submitting the EU’s first regulatory dossier for cultivated meat last year. Months later, Dutch firm Mosa Meat applied to the EU for its cultivated beef fat, which is mixed with plant-based ingredients to produce burgers and reduce overall costs.

Germans envision 3D-printers becoming mainstream

“Food printers are currently still relatively expensive and rely on specialised ingredients. Therefore, they are not yet suitable for mass production, but are primarily used in the catering and food industry,” explained Margareta Maier, digital farming officer at Bitkom.

Still, 16% of Germans say they’d like to use a 3D printer to produce food tailored to their preferences and needs, and 15% believe they will become an integral kitchen equipment in the future.

“The process makes it possible to give products an appearance and texture similar to conventional meat – but with a significantly smaller ecological footprint,” Maier said. “More and more people are open to plant-based alternatives and innovative technologies – 3D-printed food could therefore become even more important in the future.”

Cultivated meat manufacturers often use 3D printing to build scaffolds that dictate how cells grow and differentiate. Israel’s Steakholder Foods, Believer Meats and Aleph Farms, and California’s Good Meat BlueNalu have all been known to leverage this tech.

3D printing is among a number of techniques used to make scaffolds, with manufacturers also able to use polymer spinning technologies (like electrospinning), decellularisation, hydrogels, and even mycelium.

Germans’ receptiveness to the tech, though, chimes with previous research. One survey found that nearly half (47%) of its citizens say they would eat cultivated meat, and that the government should support its development and help farmers capitalise on the opportunities. This comes at a time when more and more Germans are cutting back on meat; a third of its consumer want to reduce their meat consumption, and 38% want to replace it with plant-based food.

“From food tech in industry and gastronomy to smart farming in the field and in the stable, digital technologies play a central role in saving resources in food production and making agriculture more environmentally friendly, robust, and animal-friendly,” said Maier.

The post A Quarter of Germans Would Eat 3D-Printed Cultivated Meat appeared first on Green Queen.

This post was originally published on Green Queen.