While pet food brands tout the use of animal byproducts as sustainable, a new analysis shows that products made with cultivated meat generate a fraction of the emissions.

Producing meat from cellular agriculture instead of conventional farming can drastically lower the climate impact of pet food producers, according to a new analysis.

Many believe pet food to be a sustainable product due to the use of animal byproducts, since this is waste from the production of meat for human use that would otherwise be discarded. In fact, some use this argument to suggest that pet food actually offsets the impact of the human food industry.

In reality, these products aren’t emission-free, and to highlight the true reduction potential for pet food, Austrian-American food tech startup BioCraft Pet Nutrition commissioned a carbon footprint analysis of its cultivated mouse meat and the conventional beef byproducts used in the industry.

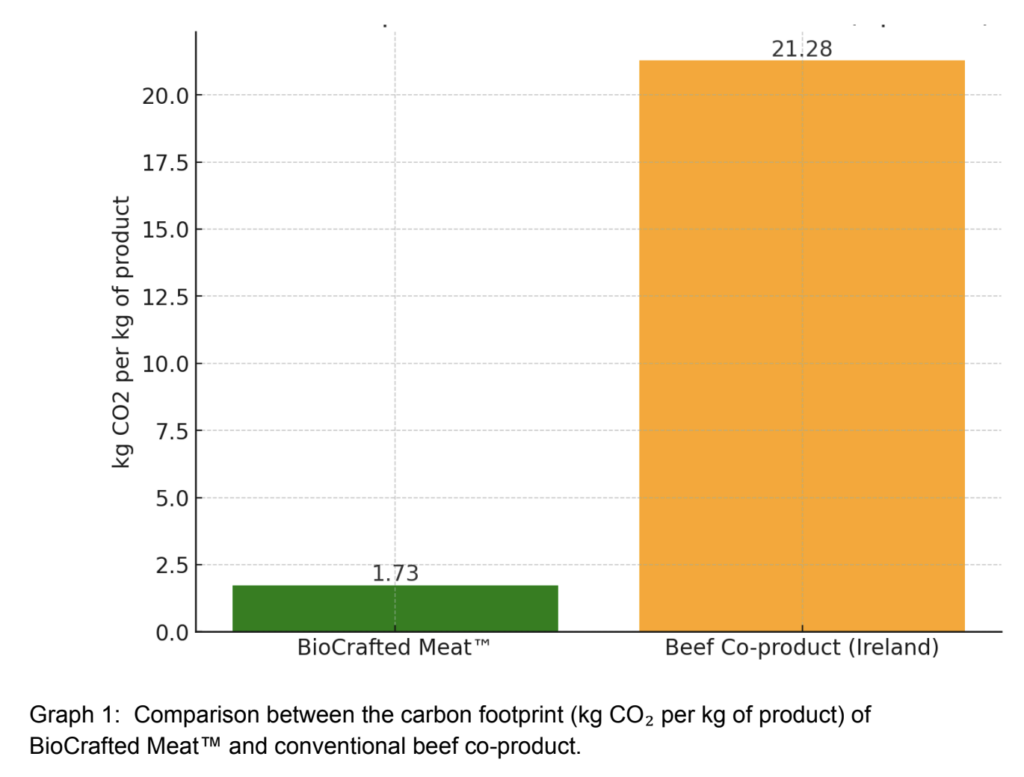

Conducted by corporate environmental consultancy ClimatePartner, the assessment showed that the firm’s BioCrafted Meat emits one-twelfth of the carbon dioxide of beef byproducts.

BioCraft co-founder and CEO Dr Shannon Falconer ascribed the difference to the startup’s “unique production process, which harvests the full contents of the bioreactor, which also makes it quite different from cultivated meat production”.

Byproducts don’t make pet food as sustainable as you think

The analysis was based on internationally recognised methodologies, including the Greenhouse Gas Protocol Corporate Accounting and Reporting Standard (GHG Protocol), and used emissions factors from databases like Ecoinvent and the UK Department for Environment, Food and Rural Affairs (Defra).

BioCraft’s emissions were calculated based on its ingredients being produced with mixed energy in Europe, considering all relevant greenhouse gases and calculating their values as CO2 equivalents.

ClimatePartner’s analysis revealed that, based on standard EU beef production processes, beef byproducts emit 21.28kg of CO2 per kg. In comparison, BioCraft’s cultivated mouse meat produces just 1.73kg of CO2 for the same amount, offering manufacturers a 92% reduction.

While the use of offal, bones, blood, and fat instead of prime beef cuts makes many consumers regard byproducts as low-impact alternatives, that isn’t necessarily the case. “The environmental impacts of raising cattle are caused by the entire animal, not merely the portions used in the human food supply,” said Falconer.

Research shows that only around a quarter of animal byproducts produced in wealthy nations go towards the pet food industry, which competes for these ingredients with the likes of the livestock, energy and pharma sectors.

Some studies have contended that byproducts actually have a worse environmental impact because of their poor nutritional content. “For dog food, using animal byproducts rather than human-grade meat requires 1.4 times more livestock carcasses, and for cat food, 1.9 times more,” a recent analysis found.

“Hence, animal byproducts are less efficient to produce than human-grade meat. Their production requires significantly more livestock carcasses. This has the potential to increase the number of livestock animals required, and the associated environmental impacts,” its authors explained.

Cultivated meat presents climate wins as alternative pet food heats up

BioCraft’s unstructured ingredient is grown from cultured mouse cells and doesn’t require additional downstream processing. It’s also cost-effective. Typically, animal-derived growth media – the mix of proteins, sugar and nutrients that feed animal cells in a bioreactor – cost hundreds of dollars per litre.

BioCraft has developed a plant-based growth medium formulated to provide a nutritious boost to the end product, allowing its pet food ingredient to be priced at $2-2.50 per pound.

Importantly, the carbon footprint analysis looked at manufacturer-driven life-cycle stages – from raw material extraction and pre-processing to packaging, delivery, and disposal. It didn’t take into account the emissions from the manufacturing of final products or consumer use, since BioCraft solely operates as a B2B supplier of raw materials.

Still, this gives a glimpse of the emissions reduction potential for pet food producers that swap beef byproducts with cultivated meat. BioCraft’s ingredient has a comparable consistency and nutritional profile to conventional slurry, and so can be used as a one-to-one replacement in wet or dry pet food at similar inclusion levels.

The firm recently received registration from Austrian authorities to use Category 3 animal byproducts (ABPs) in the EU, allowing it to sell the cultivated mouse meat to pet food producers in the region. It is already working with Partner in Pet Food and Prefera Petfood to bring the ingredient to market, having earmarked early 2026 for its debut.

Czech startup Bene Meat Technologies was the first to register cultivated pet food as an EU feed material back in 2023, although it did so under the fermentation category instead of as an ABP. It claims that its cultivated meat generates 84-95% fewer emissions than beef, though this analysis did not focus specifically on byproducts.

It is a ripe time for alternative pet food. The UK became the first country where consumers could buy cultivated meat for their cats and dogs off the shelves this year, while Germany’s Marsapet rolled out a kibble product for dogs using Calysta’s gas-fermented FeedKind protein in Europe.

Meanwhile, British vegan pet food maker The Pack was acquired by Prefera Petfood, and fellow London-based startup Omni saw sales shoot up by 130% with 20,000 new customers in the three months after securing an investment from Steven Bartlett and Deborah Meaden on Dragons’ Den.

Elsewhere, one US startup has conducted feeding trials in pursuit of regulatory approval in the US, and Bene Meat has filed for approval there too. Meanwhile, California’s Friends & Family Pet Food Co has inked two deals to launch stateside and in Singapore.

The post Cultivated Meat Generates 92% Fewer Emissions Than Beef Byproducts in Pet Food appeared first on Green Queen.

This post was originally published on Green Queen.