UK firm Multus Biotechnology has unveiled an animal-free media formulation for cultivated meat, allowing companies to eliminate serum from their products.

To ease ethical concerns, optimise production and lower costs, British company Multus Biotechnology has developed an animal-free culture medium to replace fetal bovine serum (FBS) for cultivated meat.

Animal serum contains high amounts of protein, alongside growth factors, hormones, antioxidants, lipids, and other components that replicate a fetal-like state for cell proliferation. It has been used as a key component in cell culture for decades.

The problem? It can contain unknown amounts of thousands of different components and poses the threat of antibacterial contamination. It’s also in short supply and thus highly expensive, and has sparked ethical concerns about the use of fetal animals to produce cultivated meat.

Over the years, many companies have moved away from cultivated meat to use animal-component-free (ACF) media formulations for production. Multus’s latest innovation, developed with the help of artificial intelligence (AI), adds to the list of solutions for producers in this space.

How Multus uses AI to develop serum replacements

The new serum replacement has been described as the first commercially available ACF media formulation for porcine adipose-derived stem cells. These are multipotent cells that differentiate into fat, bone and cartilage, which makes them valuable for a variety of applications, from food production to regenerative medicine.

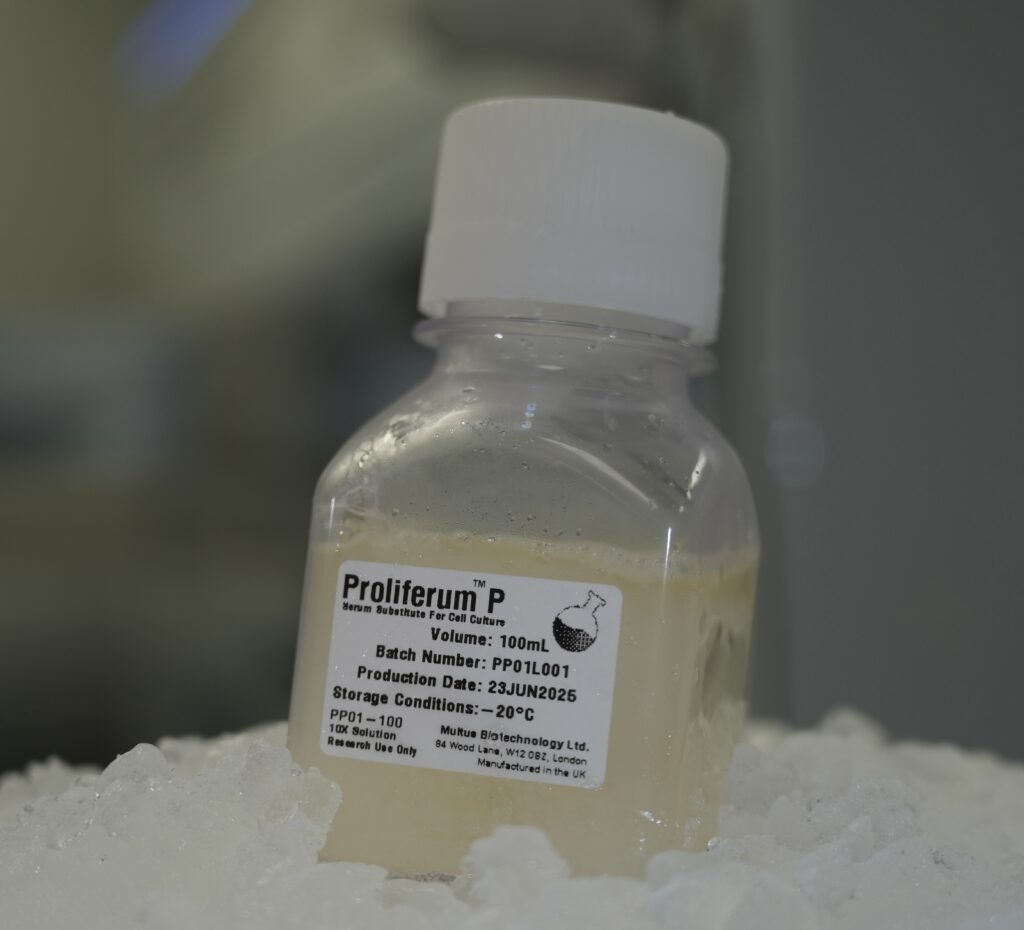

Titled Proliferum P, the ACF formulation is said to match or outperform the functionality of FBS, while maintaining critical stemness characteristics and adipogenic differentiation capacity.

Traditionally, media development is expensive, labour-intensive, and slow – it can take two to four years to develop FBS alternatives, which delays product roadmaps. Multus uses AI and automation to speed things up, creating machine learning models and integrating them with high-throughput lab automation systems.

It uses machine learning to screen dozens of potential ingredients for each cell to figure out the specific formulation, and automate media preparation, cell culturing, data collection, and data analysis.

“We’ve built a process that not only accelerates the media development process, but also customises it to specific cell types,” said Soraya Padilla, project lead for Proliferum P.

The technology helped Multus develop Proliferum P in less than six months, while optimising for cost, cell growth and functional performance. This was faster than Proliferum B, a serum replacement for bovine fibroblasts that was created in nine months.

Proliferum P is said to be quality-controlled and scalable, and is available for testing and evaluation by companies working with porcine ASCs to create food and healthcare products.

Serum-free media becoming the norm for cultivated meat

Multus, which has raised over $14M to date, said the launch represented a “breakthrough in both development speed and performance”, and showcased its platform’s ability to deliver optimal formulations for diverse cell types.

“Our platform doesn’t just allow us to match industry standards – it ensures we continuously raise the bar,” said co-founder and CEO Cai Linton. “With Proliferum P, we’re delivering a superior product to FBS while demonstrating how AI and automation, in the hands of our experienced scientists, can transform biotechnology development timelines.”

It marks the firm’s third product launch in six months. In May, it introduced its food-grade basal media, developed in tandem with global food and feed ingredient companies.

Multus is working with bioprocess optimisation firm New Wave Biotech to create more affordable inputs for cultivated meat makers, as well as with Quest Meat to develop a cell culture ingredients platform as part of a £1M project co-funded by the UK government. And last year, it opened a food-safe media manufacturing facility that can support 500 tonnes of cultivated meat per year.

Efforts to eliminate FBS from cultivated meat production have been growing. Dutch firm Mosa Meat is a pioneer in this space, having removed animal serum from its products in 2019 and later making its serum-free formulation open-source.

Elsewhere, Japanese startup IntegriCulture developed cultivated chicken and duck liver cells using a serum-free medium, and South Korea’s CellMeat and Simple Planet have created serum-free cell culture media too. Meanwhile, Eat Just’s Good Meat won regulatory approval for its serum-free media in Singapore back in 2023.

By replacing animal serum in its cultivated pork production tech, US startup Clever Carnivore has achieved industry-leading media costs of $0.07 per litre. A 2023 industry survey by the Good Food Institute showed the benefits of eliminating ASF formulations, with 74% of companies reporting identical or better results after establishing a cell line in serum-free conditions.

The post British Startup Multus Taps AI & Automation to Create Serum-Free Media for Cultivated Meat appeared first on Green Queen.

This post was originally published on Green Queen.