EdiMembre has spun off from Merck’s MilliporeSigma to commercialise an edible membrane technology for sustainable foods, starting with whole-cut cultivated meat and high-protein pasta.

In Massachusetts, EdiMembre is a new startup hoping to enable scalable manufacturing for future food companies with hollow fibre membrane technology.

The food tech firm has spun out from MilliporeSigma, the US life sciences arm of Germany’s Merck Group, with an exclusive licence to commercialise its edible membrane platform.

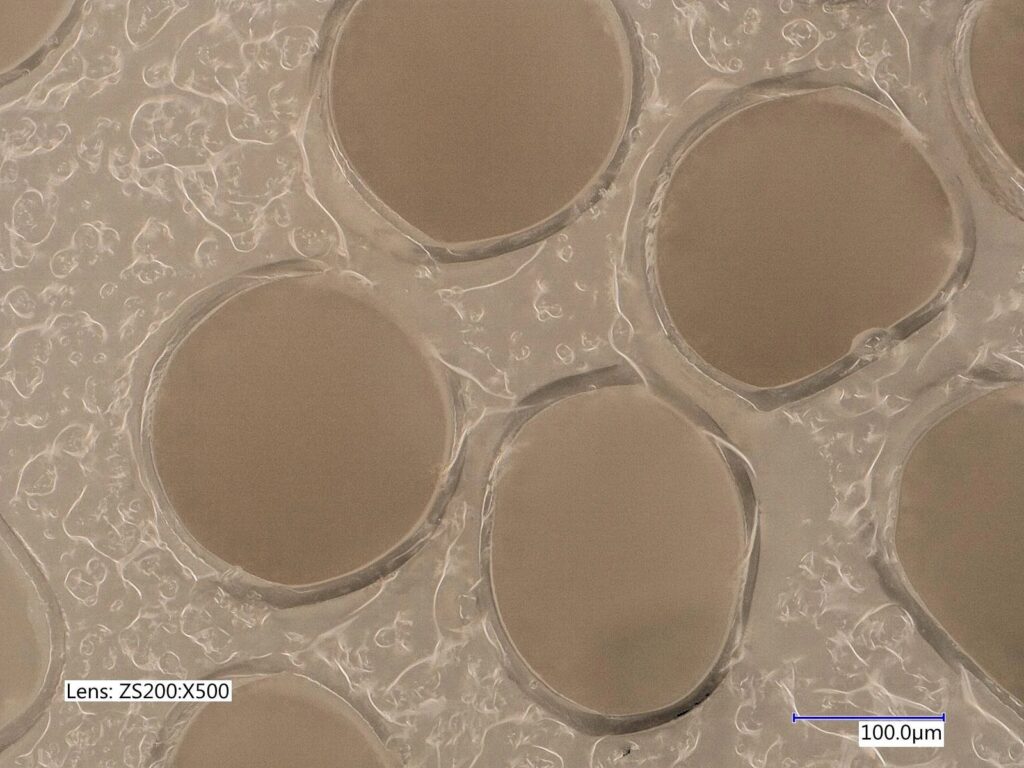

“Inspired by traditional membrane formation techniques, EdiMembre uses a patented phase-inversion approach to form micro- and nanoporous membranes from legume protein isolates. These membranes have the ability to pass large molecules through them, while promoting cell attachment,” co-founder and CSO Ryan Sylvia tells Green Queen.

EdiMembre has already developed countertop bioreactors to create whole-cut pieces of cultivated meat and high-protein pasta made with legume protein isolate. “Beyond this, we can tune the physical properties of the membrane, opening up a range of culinary experiences and applications,” adds Sylvia.

As it transfers the tech from MilliporeSigma, the startup has raised $500,000 in pre-seed investment from Siddhi Capital, Replicator VC, Meach Cove Capital, Alwyn Capital, and Cellular Agriculture Ltd, among others.

“Over the next few weeks, we will be unpacking and building our beta pilot machine to start manufacturing edible fibres in our new headquarters at the Atlas Commercial Kitchen in Woburn, Massachusetts,” notes co-founder and CEO Timothy Ryan Olsen. “Two key members from the technical project team at MilliporeSigma have been hired and are onboarded.”

How edible membrane tech can transform future food manufacturing

MilliporeSigma’s cultivated meat programme led to the development of a strong IP portfolio and alternative protein partnerships, which presented an externalisation opportunity to fine-tune the tech further with AI-led company builder Mantro.

The latter is managing MilliporeSigma’s stake in EdiMembre, which will develop and commercialise the patent-protected edible membrane tech to deliver efficient solutions for future food manufacturing.

“EdiMembre’s flagship technology is CraftRidge, which is the patent-protected edible hollow fibre bioreactor for growing structured whole-cut cultivated meat at scale,” explains Sylvia. “Thus far, we have worked with partners to demonstrate application for multiple cell types and species, while using single-cell, aggregate, and adherent cell bioprocess modalities. Today, we can offer bench-top devices for growing a few grams, but are actively working towards kilogram scales.”

The startup has demonstrated membranes with several off-the-shelf legume protein isolates, with soy, mung or lentil-derived options preferred most. “From a labelling standpoint, this becomes very attractive, since the membrane is composed of a single material: legume protein isolate,” he says.

The isolates can result in pasta with plant protein content higher than 80%, well above the market standard of 15-40%. They can also help make whole cuts of cultivated meat. Scaling up these novel proteins is a major challenge that requires large amounts of capital expenditure.

“Our scaled-out edible hollow fibre bioprocess approach alleviates this capex burden for the industry while solving the harvest and whole-cut formation challenges,” Sylvia outlines. “The technology platform has been shown to accommodate multiple cell types, species and bioprocess modalities. To use our device is straightforward – you put your cells in, use your bioprocess, harvest, cook, then eat.”

He adds: “Depending on the end user’s preference, we can easily control the amount of hollow fibre membrane that goes into the bioreactor. For most users, our protein hollow fibres are expected to be in the bulk range of 30-50% of the final product, which is great as it will contribute to the final protein content of the cultivated meat.

“The cultivated meat companies can fill the lumen of the fibres with fat content as a post-processing step, allowing for homogenous distribution of fat content throughout the whole-cut meat.”

EdiMembre targets cultivated protein startups and Big Meat

EdiMembre plans to leverage a B2B consumables model. “CraftRidge is a single-use edible hollow fibre bioreactor consumable part that will be manufactured and available off the shelf, or made to order for custom cultivated meat products,” explains Olsen.

He expects cultivated meat and seafood startups that are bringing products to market today as its initial customers, with future clients including large meat producers that have integrated cell-cultured protein into their supply chain.

“Over the last few years, we have already built partnerships with the leading cultivated meat startups to kickstart industry-relevant testing of our prototypes. They are the true experts with their cells and bioprocess, while also having the vision for the product concept they are bringing to market,” he says.

“As cultivated meat companies are successful in creating products 2.0 and 3.0 with CraftRidge over the next few years, licensing opportunities will naturally present themselves both for access to the consumable for production of cultivated meat and also the equipment used for manufacturing the edible hollow fibres and single-use devices.”

Olsen acknowledges that to enter the market, CraftRidge would need to show strong bioprocess performance, regulatory alignment and seamless integration into existing cultured protein workflows. So it’s critical to work closely with its partners to secure feedback and technical insights at each development stage.

“The go-to-market strategy began with industry testing of our prototypes over the last year. EdiMembre provided the device with a basic protocol, and the cultivated meat startups shared data and bioprocess feedback. We use feedback to set our product specifications with the vision of allowing the launch of a product that can be used by as many customers as possible,” the CEO says.

“As with all biotechnology, scaling sizes are required for the manufacturers to build their bioprocess. After the prototype stage, EdiMembre is targeting a 1kg device as the first ‘usable’ device for making significant quantities of structured cultured meat,” he adds.

“We are planning to have the first version of the 1kg device in our hands by the end of 2025. In the future, we envision a 30kg device being the industrial workhorse for large meat producers.”

Gearing up for $5M seed round

The edible membrane technology enables a broad range of applications, including substrates for cell-based leather and encapsulation of biologics. Right now, though, EdiMembre is “laser-focused” on cultivated meat, with some of its priorities including the optimisation of protein solutions, formation of bath chemistries, increase of fibre-spinning speeds, and the design of scaled versions of its spinning machines.

“As we build for the cultivated meat industry, we are anticipating opportunistic commercial opportunities for protein pasta via licensing of our manufacturing capabilities. Early wins here would help to advance our technology readiness level across the platform, validate our capabilities, and provide early revenues for our company,” says Olsen.

With the new funds, EdiMembre is working to improve its edible hollow fibre spinning process at the benchtop scale and developing plans to make its manufacturing commercially relevant. It’s not stopping at the pre-seed round, though.

“We have already started our seed round fundraising, and are targeting $5M. These funds will be directed at building out the full pilot machine to enable production of the 1kg CraftRidge devices for delivery to customers, partnering to demonstrate a bioprocess run at the 1kg scale to produce structured whole-cut meat, advancing patent applications on scalable production processes and equipment, and continuing to build out a world-class team,” Olsen says.

The startup will now get its lab up and running and ready its platform, while forging new partnerships that multiply its existing capabilities and create early revenue opportunities. Success in the first six months would allow it to showcase both the tech and its ability to move quickly with a strong yet lean team. “This was key for securing EdiMembre’s first investors, and we know it will be absolutely paramount for our seed fundraising success, especially given the current environment.”

Funding for alternative proteins has dipped dramatically. Cultivated meat companies raised more in 2021 than in the following three years combined. And this year, the sector had only secured $35M by the first half. In the US, where EdiMembre operates, seven states have banned these proteins, and plenty of others are hoping to do the same.

Olsen, however, remains optimistic about the industry’s future, pointing to the host of regulatory wins this year. Three companies received some form of regulatory clearance in the US (one’s products are already on sale), while one startup went on sale in Australia, and another was approved to sell cultivated meat for pets in Singapore.

“The cultured meat market has seemed to ‘correct’ itself in terms of valuations and expectations from a few years ago, which has led to the current funding environment. EdiMembre’s first investors and our team are aligned in that cultivated meat is still a huge opportunity, but will just take time and hard work,” Olsen contends.

“As cultured meat companies continue to make progress with cost, scale, product development, infrastructure, regulatory, and beyond, we will do our part to be a key enabling technology partner to accelerate their efforts in bringing delicious cultured products to the global market.”

The post Exclusive: Merck Spinout Banks on Edible Membrane Tech to Produce Whole-Cut Cultivated Meat appeared first on Green Queen.

This post was originally published on Green Queen.