NoPalm Ingredients will upcycle dairy giant Milcobel’s whey permeate into its fermentation-derived palm oil alternatives and explore establishing a commercial factory by 2028.

Dutch startup NoPalm Ingredients has secured a deal to valorise a cheese industry sidestream and turn it into yeast-based fats that can replace palm oil.

The fermentation firm has teamed up with Dutch dairy processor Milcobel to use its whey permeate – a low-protein byproduct of whey processing – as feedstock for its sustainable oils.

The strategic partnership will also see the companies conduct a joint study to explore the feasibility of co-locating NoPalm Ingredients’s first commercial-scale facility at Milcobel’s Langemark site, including integration with existing infrastructure.

This would be designed to produce 6,000-7,000 tonnes of oil per year. “Combined with additional partnerships we are already exploring, this would position us to capture a significant share of the market by 2028,” Julie Cortal, NoPalm Ingredients’s chief commercial officer, told Green Queen.

The move comes weeks after the startup teamed up with contract manufacturer Nizo Food Research to build a demonstration facility at the latter’s food innovation campus in Ede. Milcobel’s whey permeate will serve as feedstock for this plant, which is set to begin operations next year.

“Our demo plant will reach full capacity in the next two years, producing around 1,200 tons of oil annually,” said Cortal, who declined to disclose the specific volumes involved in the Milcobel deal. “This is a meaningful first step toward commercial scale, proving both the technology and the market traction.”

NoPalm Ingredients co-founder and CEO Lars Langhout noted: “This partnership proves the strength of our co-location model: turning sidestreams into high-value ingredients where they are generated, reducing transport and sharing infrastructure.”

Milcobel ‘closes the loop’ with yeast oil partnership

NoPalm Ingredients uses a proprietary fermentation process with non-GMO yeasts to convert local agricultural sidestreams into yeast oils. These can be “drop-in” replacements for palm oil – they cost the same, and manufacturers don’t need to reformulate their recipes.

Those sidestreams include potato peels and, in this case, whey permeate. The latter is a liquid byproduct obtained from the filtration of whey, and can enhance browning, moisture retention and shelf life. Whey itself is the dairy industry’s largest byproduct. Around 80-90% of milk that enters cheese manufacturing facilities ends up as whey. Globally, between 180 and 190 million tonnes of whey are produced annually.

Aside from its functional properties, whey permeate can be used as a substrate for producing other value-added ingredients, including meat alternatives, precision-fermented casein, and lactic acid. NoPalm Ingredients leverages this ingredient for its sustainable oils.

Industrial trials over the last two years have showcased the feasibility of using whey permeate as a feedstock for the startup’s fermentation process. The tech consistently produced oils on specification at an industrial scale, confirming compatibility with Milcobel’s streams.

“More than 25 years ago, we made a strategic choice to focus on mozzarella. In 2022, our partnership with Arla Foods Ingredients to valorise whey protein retentate was a further reinforcement of our strategy and a significant step up in the valorisation of our whey permeate sidestream,” said Francis Relaes, managing director of Micolbel Premium Ingredients.

“This new collaboration with NoPalm Ingredients completes the loop: it brings the valorisation of whey permeate higher up the value chain, turning it into sustainable, high-value oil ingredients for food and non-food,” he added. “It not only strengthens our economic model but also reinforces our commitment to circularity principles and better impact for the planet.”

NoPalm Ingredients targets 2026 launch amid Series A raise

NoPalm Ingredients is one of several startups employing fermentation to produce eco-friendly substitutes to palm oil, which is present in nearly 50% of all supermarket items.

Palm oil production causes rampant tropical deforestation and has been directly linked to wildfires in Indonesia. Further, the industry is a threat to wildlife and human rights. Globally, supplies have increased tenfold since 1980, and increasing demand means more forests will be burnt down, a form of mass deforestation that emits greenhouse gases while removing trees that would help absorb them.

Governments recognise this: the EU’s Deforestation Regulation is set to take effect in December, and will ban the import of products with deforestation-linked palm oil (currently, 34% of palm oil imports potentially come from deforested land). Violators face fines of up to 4% of their global turnover.

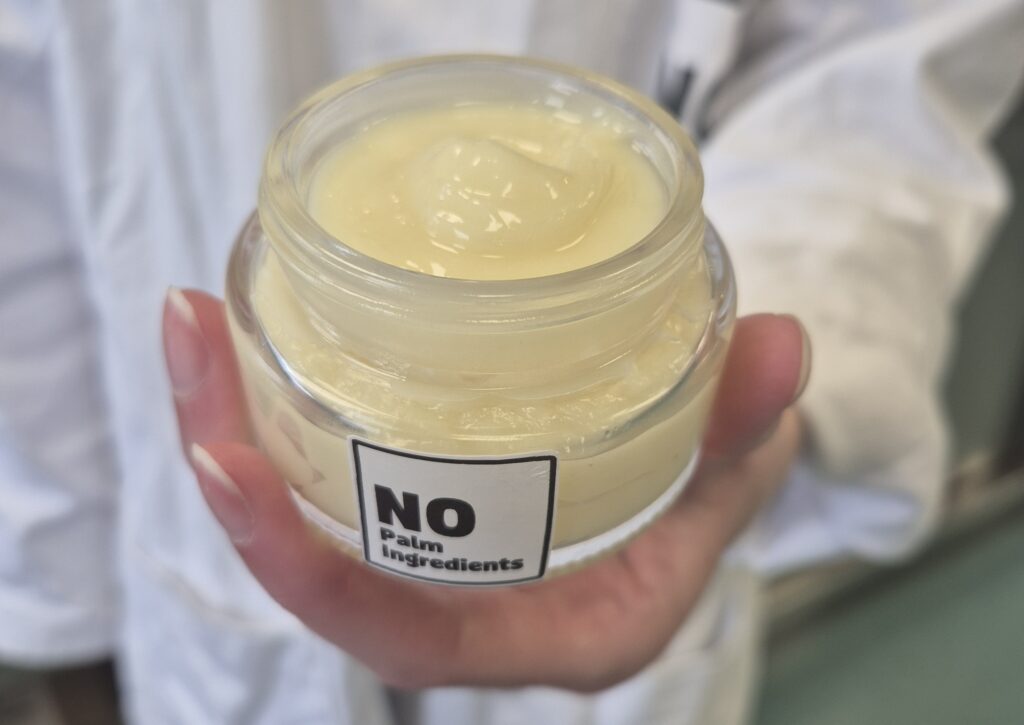

NoPalm Ingredients’s alternatives, sold under its Revóleo brand, generate 90% fewer emissions and require 99% less land. Revóleo Soft is a beige, semi-solid microbial oil meant to replace palm oil, cocoa butter, or milk fat in confectionery, baked goods, and meat and dairy alternatives; Revóleo Silk is a soft butter for personal care products like hair conditioners, colour cosmetics, and soaps.

The startup has already struck partnerships with Unilever, Colgate Palmolive, Zealandia and Those Vegan Cowboys. “Our first commercial launch is planned for next year, with a major customer already lined up,” said Cortal, though she declined to share further details. “This first launch will demonstrate not just technical feasibility, but also clear market pull from forward-thinking food companies.”

It has secured €6M in funding to date, and is currently raising a Series A round to scale up from plot to commercial production. “The funding will enable us to build our first facility, expand customer partnerships, and develop our product roadmap,” she said.

The alternative fat industry is sizzling with potential, marked by a host of recent developments. This month alone, British firm Clean Food Group received regulatory approval in the US, EU and UK to sell its yeast oil in cosmetic applications, and Estonia’s Äio completed a one-tonne production run for its palm oil substitute, eyeing market entry by year-end.

The post NoPalm Ingredients Pens Deal to Turn Cheese Byproduct Into Eco Palm Oil Substitute appeared first on Green Queen.

This post was originally published on Green Queen.