Eco materials firm Qorium has raised €22M ($25M) in Series A funding from private investors and the Dutch government to commercialise its lab-grown leather.

Qorium, a startup producing leather from cultured cow cells, has taken a major step towards bringing its sustainable material to market.

The Maastricht-based startup has secured €22M ($25M) in a Series A round from Invest-NL, a fund owned by the Dutch government, and LIOF, the regional development agency for the Limburg region. They were joined by Brightlands Venture Partners, Sofinnova Partners, and a group of high-net-worth individuals.

The capital injection from Invest-NL was made under the InvestEU guarantee scheme of the European Commission. It takes the 11-year-old company’s total funding to €30M to date.

“Qorium’s leather is a breakthrough innovation that can transform one of the world’s most polluting industries,” said Lisette Kersting-van der Boog, senior investment manager at Invest-NL. “By producing real leather without livestock, Qorium shows how biotechnology can build a more sustainable materials system.”

Qorium CEO Michael Newton called the investment a “powerful vote of confidence” in its mission to transform the leather industry. “By combining cutting-edge science with deep leather expertise and sustainable practices, we are creating real leather that offers better performance than traditional animal-derived leather, without the environmental and ethical costs,” he said.

“With Invest-NL, LIOF, and others now on board, we can take the next steps towards reinventing real leather and bring it to market at scale.”

Qorium already working with fashion and car brands

Qorium was founded by sixth-generation tanner Rutger Ploem, eco entrepreneur Stef Kranendijk, and pharmacologist Mark Post, who is best known for co-founding Mosa Meat and unveiling the world’s first cultivated meat burger.

The startup biopsies cells from living cows with the most desirable hides, which are multiplied in bioreactors with its proprietary process and medium to produce uniform collagen sheets. These are then sent to leading tanneries and global brands to be turned into leather with the same strength, durability and appearance as conventional versions.

Besides the cells, the process uses no other animal inputs, and the resulting cultivated material can integrate seamlessly into existing leather manufacturing processes, allowing it to be utilised across the full leather goods industry.

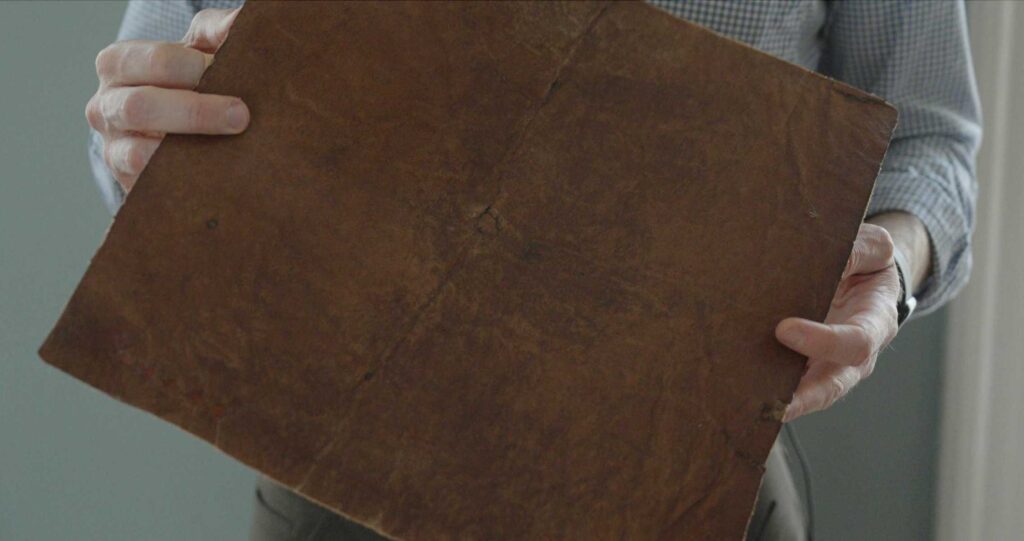

Last year, Qorium released footage of a 35x35cm sample of its cultivated leather, produced using a scaled-up tissue bioreactor that represented proof of concept for full-scale commercialisation.

That effort will be helped by the Series A raise, which Qorium will use to scale up production and install new bioreactor systems. It will appoint a new board director in the coming weeks, and has already established several commercial partnerships with high-end fashion and automotive brands to co-develop its materials and become a scale supplier.

“We’ve been on this journey with Qorium from the start, backing both the science of Dr Mark Post and the deep leather experience of Rutger Ploem,” said Guillaume Baxter, partner at Sofinnova Partners. “This investment reflects Qorium’s impressive progress to date and our strong belief in the economic and sustainability potential of its leather.”

Lab-grown leather poised for success

Advocates of leather have long viewed it as a byproduct of meat and dairy production and used that to tout its biodegradability and longevity. Critics, however, counter that it should more accurately be viewed as a co-product; in many cases, it is the primary product, and manufacturing it is an energy– and water-intensive process linked to deforestation and biodiversity loss.

There is, of course, the animal welfare aspect, given that the material is derived from cows, which drives welfare-minded consumers to look for other options. But leather production also has a much higher carbon footprint, at 110kg of CO2e per square metre, compared to synthetic and plant-based alternatives. And animal-derived leather releases lots of health-harming chemicals during tanning.

However, most first-generation vegan leather products use petroleum-derived plastic, which can take up to 500 years to break down and shed microplastics that harm marine life, the waterways, and our health.

It’s why some companies are hedging their bets on cellular agriculture. Qorium’s material eliminates the need for livestock farming, reduces production waste, lowers carbon emissions (with zero methane output), and uses low amounts of water, chemicals and inputs.

The lab-grown leather market is set to grow by 14% annually and reach nearly $400M in 2032. Several startups are advancing this technology. Parisian startup Faircraft raised $16M last year, acquired fellow cultivated leather brand VitroLabs, and is working with local leather artisans and fashion brands.

Elsewhere, Dutch firm Pelagen is working with cultivated pork maker Meatable to enhance the production, efficiency and scalability of animal-free leather for use in fashion, automotives, interiors, and more.

In the UK, Lab-Grown Leather Ltd and 3D Bio-Tissues are advancing this material, while Singapore’s ProjectEx is working on cultivating exotic leather alternatives to crocodile and ostrich. And in the US, Cultivated Biomaterials has created Angelry, a line of jewellery made with cell-based leather.

The post Dutch Startup Qorium Bags $25M to Bring Lab-Grown Leather to Market appeared first on Green Queen.

This post was originally published on Green Queen.