Spain’s MOA Foodtech has launched a new fermentation-derived ingredient that can reduce egg use in bakery, pastry and pasta formulations amid price and supply challenges.

Characterised by empty shelves and high prices where supplies are available, Europe’s egg market is still reeling from this year’s disease outbreaks.

Egg prices reached a decade-long high in the region this year. According to the European Commission, the average cost of eggs rose by 20% in October, in comparison to the same period 12 months ago, and is currently nearly 50% higher than the 2020-24 average.

Prices have, in fact, shot up consistently this year, going from €237 per kg to nearly €275 between January and October (a 16% hike), with notable peaks in Germany, Poland, Spain, and the Netherlands.

The volatility is thanks to outbreaks of avian flu and Newcastle disease, which have led to the culling of millions of chickens across Europe and the globe. At the same time, the demand for eggs has sharply increased, but anticipated price corrections have led some producers of powdered eggs to delay purchases, causing a supply gap.

Combined with the wider impact of food prices amid Europe’s cost-of-living crisis, the situation has created a perfect storm. In response, many food tech startups have come up with innovative solutions to replace eggs, from pea protein to aquafaba powders.

Spain’s MOA Foodtech, though, is using AI to offer a fermentation-derived ingredient that can reduce the reliance on eggs across a variety of applications, while retaining functionality. The aim is to provide an alternative to the price and supply instability of the ingredient and help manufacturers navigate increasingly complex allergen protocols.

MOA Q5 replicates egg functionality with one-ingredient solution

Founded in 2021, the startup uses its AI-directed fermentation platform, Albatros, to convert food industry byproducts into high-value ingredients. The tech results in a biomass boasting all essential amino acids, with a protein digestibility score of 0.9 (on par with soy, beef, eggs and casein).

MOA Foodtech is already producing an ingredient for use in pet food, meat analogues, and snacks at industrial scale – but it teased a new innovation last month. That has turned out to be the new egg reducer, called MOA Q5.

This ingredient delivers the functional performance of chicken eggs in a clean-label and supply-stable format, enabling companies to reduce or eliminate egg and eggshell declarations wherever full replacement isn’t required.

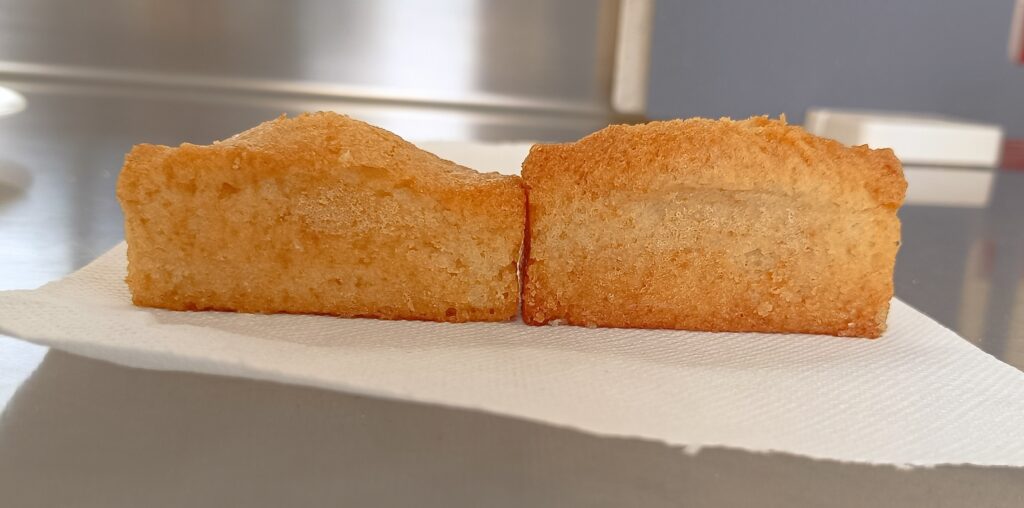

It offers equivalent emulsification, foaming, and coagulation capabilities in baked goods and pasta products, while maintaining volume, structure, elasticity, colour, and bite across a host of applications. According to the startup, it is ideal for R&D reformulation, large-scale bakery operations, pasta manufacturers, and companies making allergen-reduced premixes.

“MOA Q5 represents the next chapter in functional ingredient innovation: a fermentation-derived solution that matches egg’s performance while unlocking cleaner labels and far more predictable supply,” said Bosco Emparanza, co-founder and CEO of MOA Foodtech.

The egg-reducing ingredient will help food producers stabilise costs, simplify production and introduce circular sourcing without compromising technical performance. “Manufacturers want reliability without sacrificing quality. MOA Q5 delivers that reliability, while also offering a circular sourcing model that strengthens sustainability credentials,” he noted.

MOA Foodtech talks up ‘modern ingredient’ as egg alternatives sizzle

MOA Foodtech showcased the single-ingredient egg reducer at the Food Ingredients Europe trade fair in Paris (October 2-4), which Emparanza called the “perfect stage” for its debut. The ingredient will be featured in baked goods like muffins and cakes.

“We’re excited to show manufacturers what’s possible when biotechnology, AI, and circularity work together: a truly functional, scalable alternative that performs like eggs, but behaves like a modern ingredient.”

The startup is among several startups that have come out with functional vegan egg replacers for B2B applications this year. Dutch firm Revyve, for instance, is also using fermentation to produce a yeast protein that can substitute eggs in various food and drink products.

French player The Very Food Co, meanwhile, introduced a powdered aquafaba product that can fit into the lines of artisan bakers and industrial manufacturers alike, and Israel’s Meala rolled out Groundbaker, a pea protein innovation that offers the same gelling, binding, emulsifying and foaming attributes of eggs.

MOA Foodtech’s innovation comes months after it received €14.8M from the European Innovation Council, €12.5M of which was contingent on matching funding from private investors. “We have planned the round for the end of next year, and we already have more than 50% of the required private investment committed,” Emparanza told Green Queen last month.

He was speaking after the launch of the MOA Box, a turkey service for manufacturers that uses its AI and fermentation tech to produce upcycled starch ingredients without the typical cost, time and regulatory barriers.

“With our AI platform and fermentation expertise, we can offer a fast, de-risked, end-to-end solution that transforms waste into new revenue streams,” the CEO explained. “It allows our partners to unlock value, improve sustainability performance, and differentiate their portfolios, while positioning MOA at the centre of a circular, scalable, and economically attractive ingredient ecosystem.”

The post Spain’s MOA Foodtech Uses AI to Create Fermentation-Derived ‘Egg Reducer’ appeared first on Green Queen.

This post was originally published on Green Queen.