Harmony Baby Nutrition has secured R$31.8M ($5.8M) from the Brazilian government to create breast-milk-inspired infant formulas through fermentation and set up a new R&D centre.

Biotech startup Harmony Baby Nutrition is aiming to bridge the gap between infant formula and breast milk through fermentation.

The biotech firm has been awarded R$31.8M ($5.8M) in funding as part of the Brazilian Development Bank (BNDES) and Finep’s (Brazilian Innovation Agency) public call to establish research and innovation centres in the country.

The joint action programme is one of Brazil’s flagship innovation financing schemes, part of its Nova Indústria Brasil policy, with a total of R$3B allocated to bolster domestic innovation.

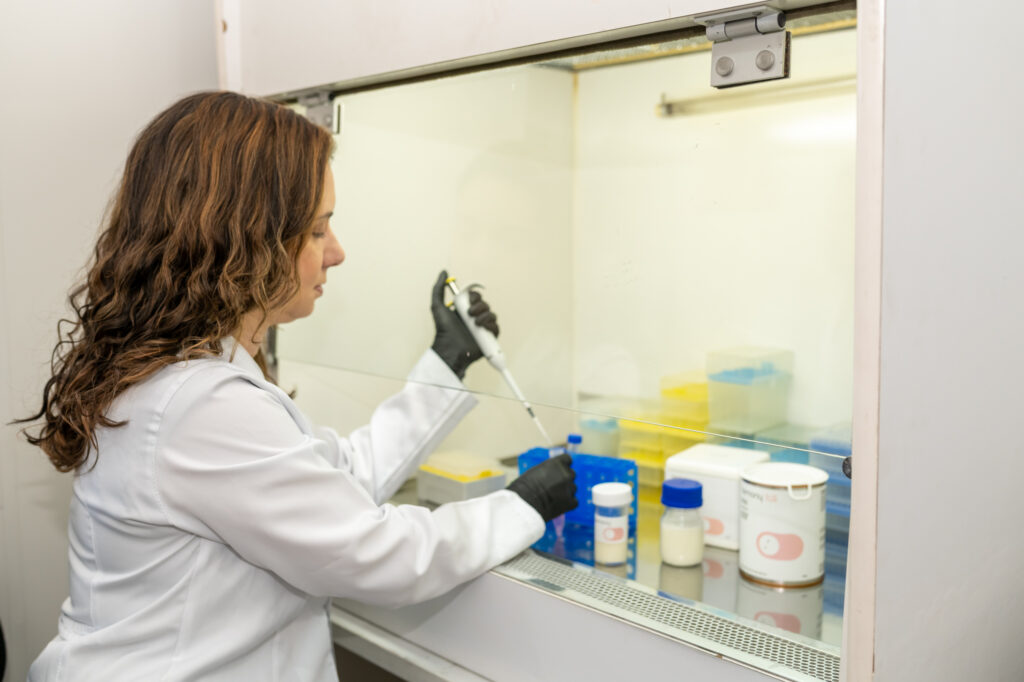

Armed with the fresh capital, Harmony will set up a new R&D centre in Belo Horizonte, focused on developing a wide range of human-milk-inspired infant formulas.

“The funds will be used to scale production for our first commercial launch and to build the commercial infrastructure needed to reach families who depend on products like ours,” founder and CEO Wendel Afonso tells Green Queen.

“Until now, our team has been primarily composed of scientists focused on R&D. As we transition from development to market entry, we need to expand our capabilities across manufacturing, quality, marketing, and customer support.”

Harmony exploring lactoferrin, casein, albumin and more

Afonso founded Harmony while pursuing an MBA course at the MIT Sloan School of Management, when he was inspired to develop a new class of hypoallergenic formulas after his own daughter suffered from formula allergies.

She isn’t alone. Every year, most of the world’s 130 million newborn babies are fed infant formula at some point; roughly 2-3% of babies are allergic to cow’s milk, and up to a sixth suffer from some kind of discomfort, according to parental reporting.

Further, 5-10% of women are physiologically unable to breastfeed, and many more say they’re not producing enough or have nutritional deficiencies in their milk. In the US, less than half of women continue to exclusively breastfeed after three months, and only a quarter keep doing so at six months, the recommended period by the American Academy of Pediatrics.

Harmony is addressing this problem by developing formulas that dramatically reduce added sugar, eliminate reliance on dairy (which is responsible for 80% of their carbon footprint), and taste significantly closer to breast milk.

“Our goal is to replicate the form and function of breast milk, beginning with the hypoallergenic segment, where today’s standard of care is the most outdated,” explains Afonso. “For our first generation, we focus on building a strong base matrix for a hypoallergenic formula that is nutritionally robust. This foundation allows us to progressively substitute cow’s-milk-derived proteins with recombinant human breast milk proteins in future generations.”

He notes that first-generation products don’t contain recombinant proteins, instead serving as a stepping stone towards fully humanised infant formulas: “Our goal is to progressively replace its cow’s milk components with human milk ingredients produced through precision fermentation.”

This process involves inserting specific DNA into microbes to teach them to produce desired molecules when fermented. The recombinant proteins selected for those future lineups are guided by their biological functions in breast milk, like supporting immunity, digestion, and nutrient absorption, and contributing to the stability and performance of the formula.

“We will begin with functional proteins such as lactoferrin, which play critical roles in bioactivity and infant development, followed by others like alpha-lactalbumin, human caseins, and human albumin,” says Afonso. “Through strategic partnerships, we ensure scalable production while meeting the highest regulatory and nutritional standards.”

Partnerships in place with co-manufacturers

Harmony won’t produce the precision-fermented breast milk proteins in-house; instead, it will partner with established recombinant milk protein manufacturers and ingredient suppliers with commercial-scale capabilities.

“We work with specialised contract manufacturing organisations for blending and quality-controlled production,” says Afonso. “Our recombinant protein partners already operate at multi-tonne annual production capacity, which is more than sufficient to support our projected demand for both pilot and commercial volumes.”

He adds: “For formula manufacturing, scalability itself is not a bottleneck. Infant formula is a well-established production category with ample global capacity. The real focus is ensuring stringent quality and safety controls, especially for hypoallergenic products, where preventing cross-contamination with intact cow’s milk proteins is critical.

“We have already secured manufacturing partners capable of dedicated or segregated production lines, aligned with Food and Drug Administration (FDA) and Codex requirements, and able to scale volumes as we grow.”

Harmony’s new R&D centre will serve as its global research hub, and it’s set to commence the implementation of the facility in the first half of 2026. The expansion, spanning around 250 sq m, will include advanced labs dedicated to R&D and quality control, and an application plant equipped with high-precision and efficient technologies.

The development will see the firm hire 25 professionals, including at least five nutrition scientists. These specialists will contribute across scientific, technical, administrative, and operational domains.

They will develop and assess the performance of novel formulations catering to diverse clinical and nutritional needs, and investigate bioactive ingredient properties, with a particular emphasis on achieving a high degree of compositional and functional similarity to human milk.

Navigating regulatory challenges for recombinant proteins in infant formula

Harmony is targeting the US for its initial launch, where its headquarters, core team, and regulatory strategy are based.

Regulation has been a sticking point for alternative formulas here. To get approved for sale, these products have to undergo a complex, time-consuming process, which involves comprehensive testing based on strict standards, nutrient analysis, ingredient safety assessments, comparative studies with breast milk, and more.

However, the US government’s 2026 budget, approved by President Donald Trump last month, includes language directing the FDA to streamline and accelerate the regulatory pathway for new dairy- and soy-free formula products.

“We continue to pursue advocacy and scientific engagement in the US to support the development of a formal regulatory framework for recombinant human milk proteins. While the US remains our primary commercial market, the regulatory pathway for novel ingredients is still evolving,” says Afonso.

Brazil is Harmony’s second target market, where it has already established strategic partnerships and will set up the R&D hub, with a team entrenched in the country’s infant nutrition ecosystem. The South American nation is one of the largest markets for formula, but lacks domestic manufacturing for specialty, hypoallergenic products.

“As a result, nearly all formulas are imported and subject to high import taxes, creating significant cost and accessibility barriers for families. By establishing a local footprint and eventually enabling domestic production, we aim to reduce reliance on imports, improve affordability, and increase product availability for Brazilian caregivers, and [plan a] potential expansion to Latin America,” says Afonso.

Is Brazil’s regulatory framework any better? He explains that recombinant milk proteins are regulated as novel food ingredients. “Their approval requires demonstrating safety through scientific studies (including toxicology and allergenicity), submitting a complete technical dossier with identity, production process, and specifications, and justifying their use in specific food categories,” he says.

ANVISA, the local authority, then evaluates the dossier and may request clarifications, before issuing the approval once safety and technological suitability are confirmed.

“Recently, ANVISA has also been revising the regulations for infant formulas and updating the regulatory framework, progressively incorporating new ingredients based on the latest scientific evidence, which represents an opportunity for the discussion and evaluation of new ingredients such as recombinant proteins,” notes Afonso.

Harmony eyes global markets amid scale-up

The company isn’t stopping at the US or Brazil. “For our future generations that incorporate recombinant human breast milk proteins, the earliest geographies for regulatory submission will likely be Australia/New Zealand and Singapore,” says Afonso.

“These agencies have some of the most innovation-friendly regulatory environments for novel ingredients in infant nutrition and offer clearer, more established pathways for evaluating new proteins,” he explains.

In the near term, though, Harmony will focus on commercialising Melodi, a toddler formula inspired by the composition of breast milk. Intended for children aged 12 months and above, it has demonstrated 61% higher sensory preference than standard hypoallergenic products in independent studies.

“Instead of relying on corn syrup solids, which are commonly used in legacy products, we use lactose, the natural carbohydrate found in human milk, to better support energy metabolism and the development of a healthy microbiome,” he says.

“We also include the human milk oligosaccharides at the maximum allowed levels, as these bioactive components play an important role in immune support and gut health.”

As it presses ahead with the move into fermentation-derived recombinant proteins, Afonso identifies the evolution from a “science-driven organisation into a commercially successful company” as Harmony’s biggest challenge.

“Until now, our focus has been on R&D, and we have successfully achieved all major technical milestones. The next phase requires scaling manufacturing, building a customer-facing organisation, and executing a strong market entry strategy,” he explains.

“To accomplish this, we will leverage the deep industry experience of our founding team while expanding beyond our current scientific base to bring in commercial, operational, and marketing expertise.”

Harmony is among several startups exploring precision fermentation to produce recombinant breast milk ingredients, including Helaina, All G, Eclipse Ingredients, PFx Biotech, Yali Bio, The Live Green Co, and Checkerspot. Elsewhere, Nūmi, developing cultivated breast milk with as many constituents as possible.

The post Exclusive: Brazil Govt Pumps $6M in Biotech Startup to Close Gap Between Breast Milk & Baby Formula appeared first on Green Queen.

This post was originally published on Green Queen.