Exercise can be more sustainable now, thanks to Community Clothing’s new Organic Athletic sportswear line, which is free from plastics and can decompose in your garden in as little as a week.

Community Clothing, the sustainable clothing brand and social enterprise by Scottish fashion designer Patrick Grant, has launched a plastic-free and compostable sportswear line, inspired by clothing materials from the 70s.

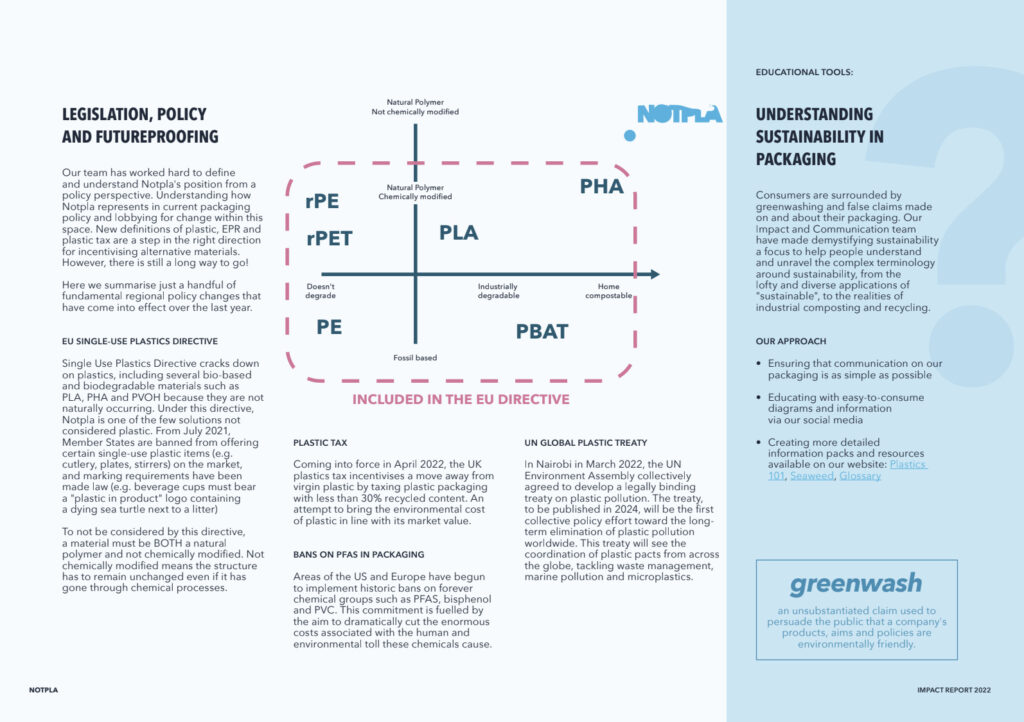

Called Organic Athletic, the 13-strong range eschews the typical use of non-biodegradable, oil-based synthetic plastic materials – chiefly polyester, nylon, polyurethane and elastane – in sports clothing, and opts for plant-based textile technology instead.

70s materials inspire new sportswear range

“Roger Bannister broke the four-minute mile wearing cotton shorts, a cotton vest and leather shoes. And I played rugby as a kid wearing clothes made from all natural materials,” Grant told the Financial Times. “None of us thought we were wearing rubbish stuff at the time.”

His childhood inspired him to explore “if it was possible to make good sportswear out of the materials we used until the late 1970s”. The new collection is a result of five years of R&D, comprising shorts, sweatshirts, T-shirts and running vests.

Made from woven or knitted certified organic cotton, as well as natural Austrian woven rubber for the shorts, Grant sourced organic athletic wear from this period on eBay. Finding most of them in Germany, he reverse-engineered each piece to assess its yarn count and durability. He explained that the toughest part was to replace elastic use.

“Elastics are made from elastane, which is synthetic and oil-based,” he said. But it’s a key tool for durability, given cotton threads are susceptible to breakages. “We had to beef up the diameter of the thread.” The resulting collection – for both men and women – is fatter in appearance, but carries a retro look akin to vintage college varsity kits, and is suitable for a variety of sports and training activities.

Sportswear’s plastic problem

Plastics and synthetic fibres like elastane (made from polyurethane), nylon, polyester and acrylic have been used in sportswear for decades for stretchability and breathability, quick-drying and waterproofing capabilities, and thermal protection. While some brands have turned to recycled fibres for eco-friendlier clothing, they still shed microplastics into the oceans and soil.

These are harmful in more ways than one. Scientists suggest that a third of all plastic waste ends up in soil or freshwater, disintegrating into microplastics that enter the food chain. These tiny particles have already been discovered in the human body, and one study estimates that we eat 5g of microplastics per week on average (about the same as eating a credit card’s worth of plastic). In fact, there are 14 million tonnes of microplastics on the ocean floor and 24 trillion pieces of microplastic on the ocean surface.

But there is an awareness issue here. A 2023 survey by global sail racing league SailGP – covering 1,500 people in the UK, US and Switzerland – found that 54% of respondents were unaware of potential toxins hiding in synthetic technical sportswear. Having said that, 72% said they’d prefer plastic-free sportswear if available. It’s these attitudes that prompted plastic-free fashion label Mover to debut a six-piece capsule collection in collaboration with SailGP, made predominantly from organic cotton, merino wool and water-based printing methods.

And while UK-based Stripe & Stare offers a TENCEL Modal-based shirt that it claims is 100% biodegradable, it contains 5% elastane. It makes the Community Clothing Organic Athletic one of the only (if not the only) sportswear ranges that are both plastic-free and compostable. Once they reach the end of life, these clothes can be shredded and added to your compost heap – within a short time, ranging from a week to five months depending on your soil, they will fully decompose and leave no remains.

“Community Clothing Organic Athletic represents the most radical change in sportswear in two generations,” Grant said in a statement. “Moving away from oil-based sports clothes to 100% natural and biodegradable means now you can exercise and play sport and not harm the planet in the process.”

The post Is This the World’s First Compostable, Plastic-Free Sportswear Range? appeared first on Green Queen.

This post was originally published on Green Queen.