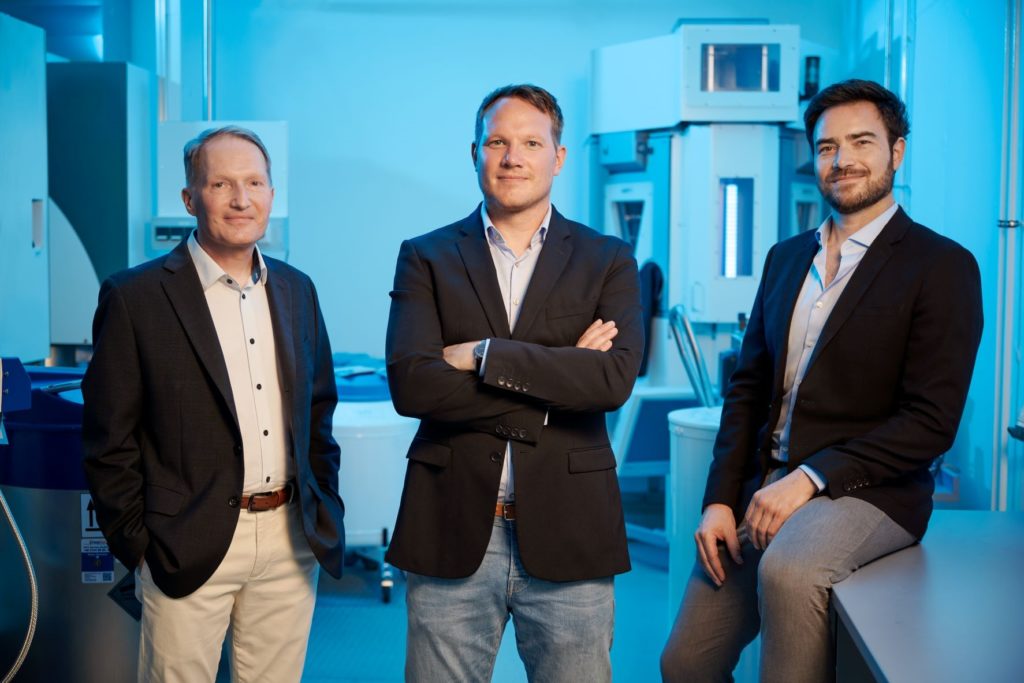

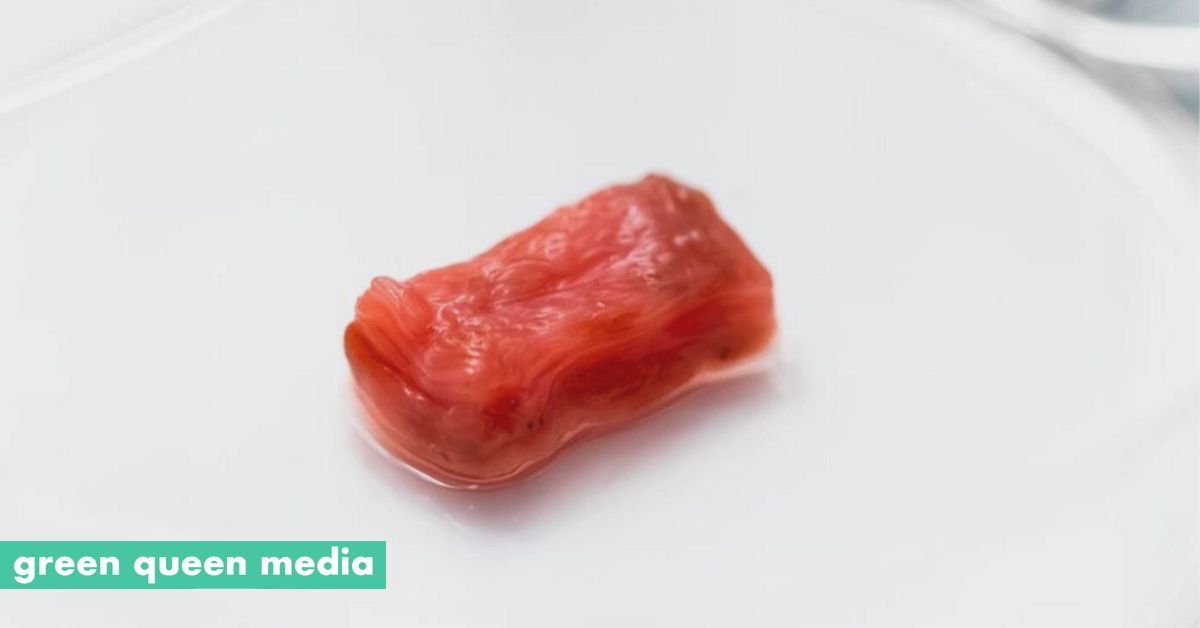

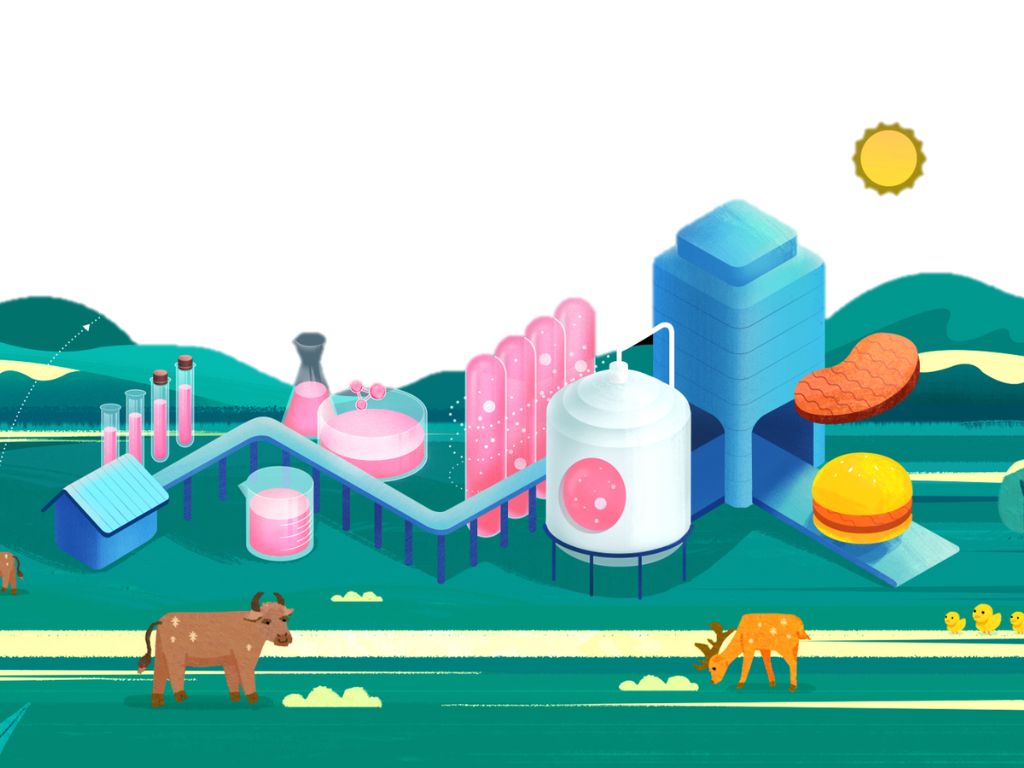

Israel-based cultivated meat producer Aleph Farms has officially submitted an application to the Swiss Federal Food Safety and Veterinary Office seeking regulatory approval to sell the world’s first cultivated beef steaks under its Aleph Cuts brand in Switzerland.

Aleph’s milestone application is a collaborative effort with Migros, Switzerland’s largest food enterprise, which has been instrumental in navigating the country’s specific regulatory approval process.

Leveraging the expertise and infrastructure of food production leaders like Migros, Aleph Farms aims to accelerate the scale-up, go-to-market activities, and commercialization of Aleph Cuts globally.

Swiss consumers are eager to try cultivated meat

As part of their collaboration, Aleph Farms and Migros have conducted extensive consumer research in Switzerland, revealing that 74 percent of Swiss consumers are open to trying cultivated meat due to factors like curiosity, sustainability, and animal welfare.

Didier Toubia, Co-Founder and CEO of Aleph Farms, emphasized the importance of collaborative efforts to ensure food security while respecting planetary boundaries. “Food systems affect everyone, and it will take a coordinated effort between regulators, innovators and incumbents to ensure food security in a way that helps humanity live within its planetary boundaries,” Toubia said in a statement.

“At Aleph Farms, we carefully consider partnerships that reflect our core values and sustainability commitments,” Toubia said. “Together with Migros, we are establishing the cow cell as the third category of food products from cattle, alongside beef and milk. We look forward to working closely with Switzerland’s Federal Food Safety and Veterinary Office to enable access to both high-quality nutrition and world-changing innovation.”

The two companies are working together to develop a go-to-market strategy for Aleph Cuts, including distribution and commercialization through fine dining food service channels in Switzerland. The country’s affinity for innovation and quality-conscious attitude towards food further contributes to cultivated meat’s growing momentum worldwide.

Global cultivated meat market

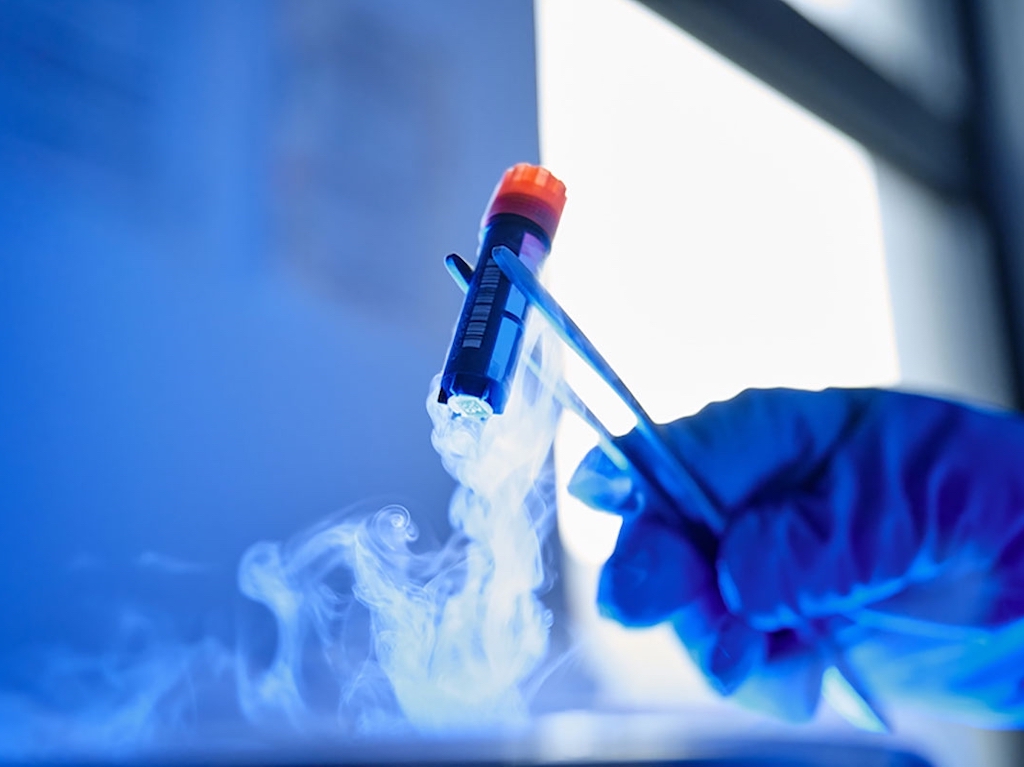

Pending regulatory approvals, Aleph Farms plans to launch Aleph Cuts in limited quantities in Singapore and Israel later this year, offering exclusive tasting experiences curated with select partners. The company’s regulatory team is currently engaging with authorities in various markets, including Switzerland, to ensure compliance with safety requirements.

Demand for cultivated meat appears high in the U.S., which recently became the second country to approve cell-based protein for sale and consumption. Two California companies, Eat Just’s Good Meat and Upside Foods, have both served their cultivated chicken to diners in collaboration with esteemed chefs Dominique Crenn and José Andrés.

Earlier this week, Good Meat announced a giveaway contest for a cultivated chicken meal at Andrés’ China Chilcano in Washington D.C. The contest was announced after the restaurant’s initial reservations to try the novel meat booked up in less than five minutes.

The post Aleph Farms Takes First Step Towards Cultivated Meat in Europe with Swiss Regulatory Application first appeared on Green Queen.

The post Aleph Farms Takes First Step Towards Cultivated Meat in Europe with Swiss Regulatory Application appeared first on Green Queen.

This post was originally published on Green Queen.